It is used by most of vessel engineer and analyst to predict the component pass or fail judgment. This table provides guides for maximum stresses allowed at various different locations.

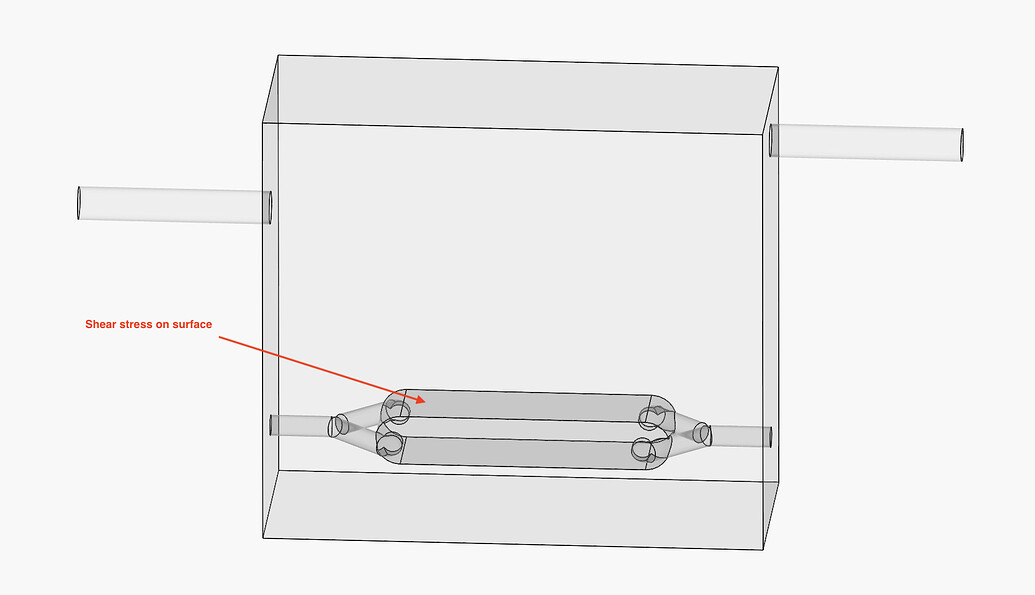

WALL SHEAR STRESS PARAVIEW PLUS

Here, stresses are further categorized as primary general membrane, primary local membrane, primary bending, secondary membrane plus bending and peak stresses. If you are doing stress assessment as per ASME, ASME VIII-2 chart Figure 5.1 provides the stress categorization and their respective allowable limits. Stress Categorization and Limits as Per ASME: Peak stress is usually used to determine the fatigue life of the components at respective SCLs. This is also always positive but not necessarily higher than the membrane + bending number. Peak stress: These stresses arehighest stress found along the SCL.Membrane + Bending: As name suggest, these stresses are sum of membrane and bending stresses.Bending Stress: Bending stress is the linearly varying stress through the thickness, which is difference in stresses from inside to outside surface.Membrane stresses are always positive and it is difficult to predict whether they are positive or negative as magnitude are provided but directions are missing. Membrane Stress: Membrane stresses are nothing but average stress across the thickness.Figure 1: Stress Classification Line & Stress Classification Plane These sections are called stress classification planes (SCPs). SCPs are flat planes that cut through a section of a component. Figure 1 presents the SCL & SCP on nozzle shell junction component. These membrane and bending stresses are developed on cross sections through the thickness of a component.

Thus, SCL tool takes stresses at each and every point along path and segregates into different stress components like, membrane stress, bending stress, membrane plus bending, peak and total stresses. In FEA, stresses are calculated at nodal points and SCL is passing through these nodes. It is perpendicular to both inside and outside surfaces of the vessel.

Stress classification Line:Ī Stress Classification Line or SCL is a straight line running from the inside to outside of a vessel. This blog article explains, how the stress linearization tool works to separate various stresses like membrane, bending & peak. FEA tools gives different types of stresses in vessel which have different safety implications. It needs skills to identify high stress locations and justify the results, furthermore the pressure vessel validation is performed with respect to ASME guidelines. Though the vessel calculations are performed with FEA software’s, but analyzing the stresses found in the pressure vessel is still difficult task. Many industries have developed FEA software’s which are being used for design validations & optimizations. Nowadays, Finite element analysis is no longer a magical tool which were used earlier only in research labs. As time passes, the vessel no longer simpler but the complexity in terms of size & shape, welding connections, materials are being observed.įurthermore, stress assessment thorough finite element analysis tool are developed and being used which allows to see stresses inside the vessel components. It is common pool for every vessel designers as well as manufacturer across the world. These are real world working standards developed for safety of vessels which were developed long time ago after several accidents and causalities were happened.

WALL SHEAR STRESS PARAVIEW CODE

The ASME Boiler & Pressure Vessel Code (BPVC) is an American Society of Mechanical Engineers (ASME) standard that regulates the design and construction of boilers and pressure vessels.

0 kommentar(er)

0 kommentar(er)